what sets crude fr™ apart from the rest

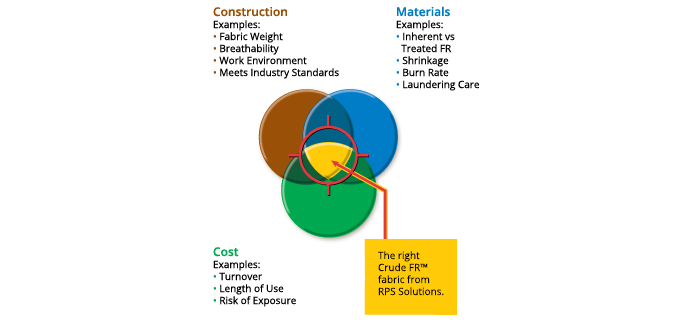

What makes RPS Solutions' Crude FR™ brand so versatile is the fact that we can customize your FR clothing needs based on the criteria detailed in the diagram below. To help aid you in this choice choose the important characteristics from each of the three categories below and cross-reference them with the available 'Fabric Comparison' chart to determine the right Crude FR™ fabric from RPS Solutions.

What also sets RPS Solutions apart from the rest is our factory direct relationships for procurement of Milliken FR™, DuPont™ Nomex IIIA® and Westex™ UltraSoft® fabrics depending on your FR garment needs and budget. With RPS Solutions you are dealing directly with the manufacturer which means our Crude FR™ products can meet any budget guidelines and allow for much shorter lead times delivering quality products faster than any other company.

Meeting industry standards is also an important component to pay attention to when selecting the appropriate FR fabric. RPS Solutions' Crude FR™ fabrics not only adhere but vastly outperform the standrds set forth in NFPA 2112; which was created for employees that work in environments where a potential flash fire hazard exists.

- Construction: Identify what's important in regards to the necessary weight of your garments; which can also have a direct correlation to the work environment intended for your employees. Typically, the hotter the climate the lighter weight fabric is optimal; but in the case of DuPont™ Nomex® the decrease in fabric weight to 4.5 oz. is not recommended because of the lack of breathability that Nomex® has. Please see info for each Crude FR™ fabric in the 'Products' section under Fabrics.

- Materials: Identify the qualities of the fabric contents to gauge what type of shrinkage and FR treatment is acceptable. Please see info on DuPont™ Nomex® to understand the difference between Inherent FR fabrics and Treated FR fabrics.

- Cost: Identify the length of use (garment life), risk of exposure and expected turnover to determine the fabric choice that fits within your available budget. DuPont™ Nomex® tends to have a higher upfront cost with respect to the Amplitude® and Ultrasoft® fabric lines; however this higher cost can be offset in the long run due to the longer garment life if your risk of turnover is low. Please see how 'FR Clothing Can Save Money' in the Why Use FR Clothing? section.

Fabric Comparisons

- Fabric Contents

- Fabric Weights

- Laundering Shrinkage (100 Cycles)

- Thermal Shrinkage (3 sec. burst)

- Burn Rate %

- Inherent FR vs. Treated FR

- Breathability *(5 = most; 1 = least)

Milliken FR™

Amplitude- 88% Cotton / 12% Nylon

- 7 oz. & 9 oz.

- 1.8%

- 2.5%

- 18.3% & 11.8%

- Treated FR

- 5