DuPont™ Nomex® fibers are heat- and flame-resistant, and are used in protective fabrics, garments, insulation, and other high-performance applications to help provide protection to millions of people worldwide. Nomex® is an inherently flame-resistant, high-temperature resistant fiber that will not melt, drip, or support combustion in air. Today, more than three million industrial workers at risk from flash fire and electric arc hazards around the world are protected by Nomex® for its unique combination of flame protection, durability, and mobility.

DuPont™ Nomex® Fibers for Heat- and Flame-Resistant Protection

Fires are unpredictable — situations can change in an instant with temperatures reaching 1900 degrees F, leaving workers vulnerable to serious injury. So for hazards like flash fire, DuPont™ created Nomex® IIIA. A blend of 93% Nomex® with 5% Kevlar® and 2% antistatic fiber, this innovative fabric helps minimize break-open, and expands to form a stable and inert barrier between the fire and skin. This gives wearers the valuable seconds they need to escape from the hazard. At DuPont™, innovation means testing beyond the basics with state-of-the-art technology like Thermo-Man®, one of the most advanced life-size thermal burn injury evaluation devices in the world today.

Dependable Protection Against Fire hazards with Nomex® III A

- Widely used by petroleum, petrochemical, chemical, and utility industries, as well as firefighters

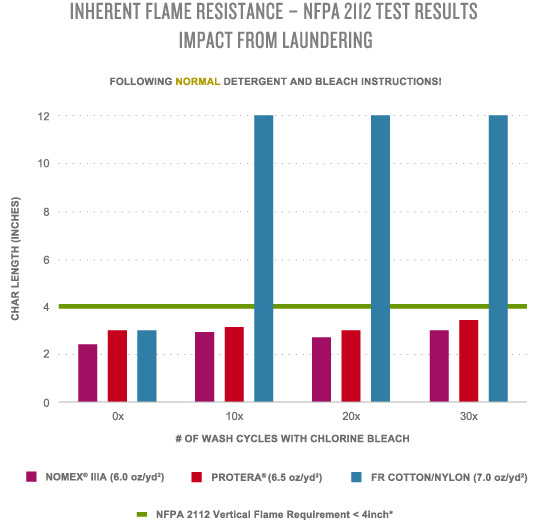

- Inherent thermal protection that cannot be washed away

- Durable and resistant to abrasion, tears, and chemicals

- Complies with NFPA 2112 Standard on Flame-Resistant Garments for Protection of Industrial Personnel Against Flash Fire

Inherent versus Treated Flame Resistant Fabrics

Inherently flame resistant fibers are materials that have flame resistance built into their chemical structures. Aramid fibers from companies like DuPont™ create inherently flame resistant fibers with brands such as Nomex®. For inherently flame resistant fibers, the protection is built into the fiber itself and can never be worn away or washed out. In the case of Nomex®, when exposed to flame, the aramid fiber swells and becomes thicker, forming a protective barrier between the heat source and the skin. This protective barrier stays supple until it cools, giving the wearer vital extra seconds of protection to escape.

The other main category is flame-retardant treated (FRT) fabrics. These materials are made flame-resistant by the application of flame-retardant chemicals. A chemical additive in the fiber or treatment on the fabric is used to provide some level of flame retardancy. During a fire, chemically dependent fabrics rely on a chemical reaction to extinguish the flame. This reaction is triggered by the heat of the fire and the amount of time the fabric is exposed to the fire. It is very difficult to determine whether protection has been compromised with an FRT fabric, testing the garment through a flame test is the only way to determine the current level of flame resistance, ultimately destroying it though.

Laundering Impact on Flame Resistance

An essential thing to keep in mind when assessing flame-resistant technologies is that inherent flame resistant properties cannot be washed out or damaged through exposure to chemicals in the workplace or laundering practices, whether at-home or commercial. FR-treated garments, however, may be damaged by chlorine bleach, the combination of hydrogen peroxide (“oxygen bleach”) with hard water, or exposure to oxidizing chemicals in the workplace.